Bioplastics in construction

Bioplastics in construction

In Germany, about 13 million tons of plastic are processed annually, over 3 million of which are used in construction. This makes the construction industry the second largest consumer of plastics, after the packaging industry.

Plastics are primarily used in non-load-bearing building components. More than half of this amount is used in pipes and conduits. Other applications include window and door frames, insulation materials, and floor coverings. Plastics also play a significant role in smaller quantities, such as in adhesives, sealants, and coatings.

The most commonly used plastics include:

- Polyethylene (PE): used for pipes and cables

- Polyvinyl chloride (PVC): used for window and door frames

- Polystyrene (PS) and polyurethane (PU), which are mostly used in their expanded form or as a foam for insulation materials

Bioplastics

Bioplastics, also called bio-based plastics, are made from renewable resources such as starch, sugar, cellulose, lignin, or vegetable oils. The first developments in bioplastics date back over 150 years, but they lost importance with the rise of the petroleum industry.

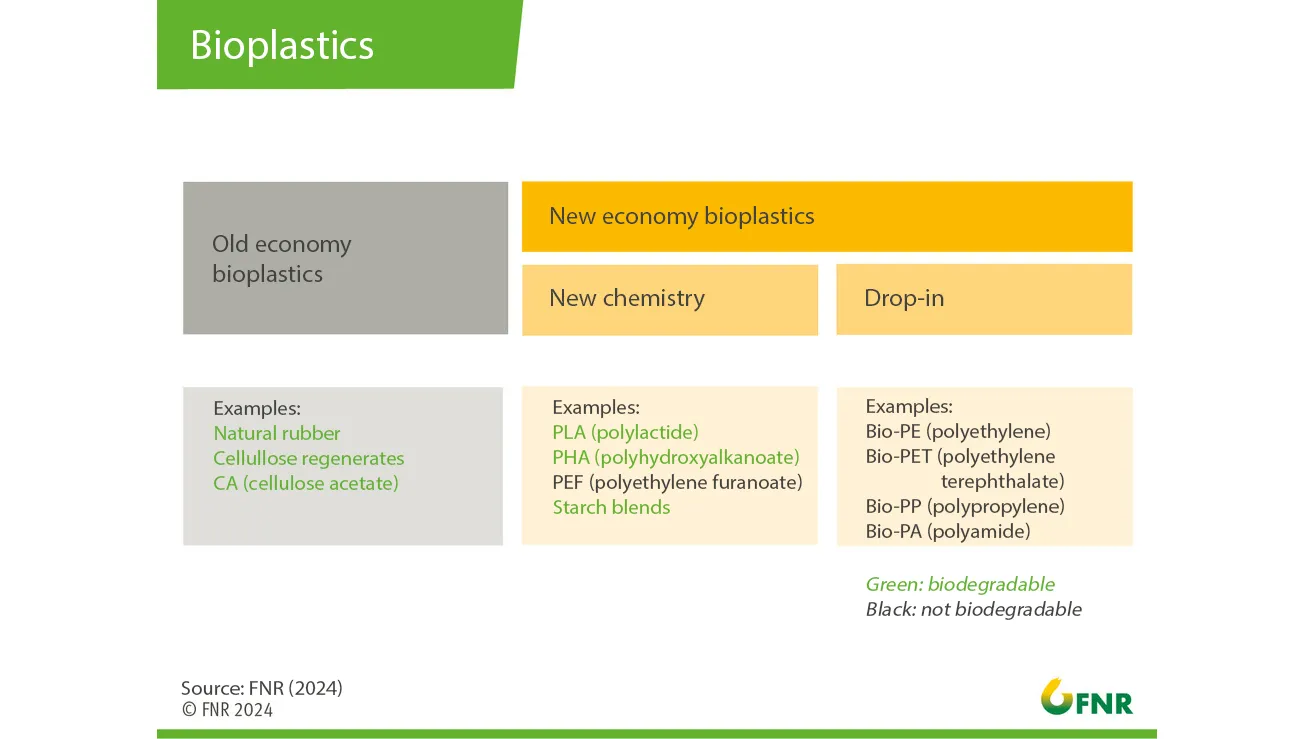

However, new bioplastics have been specifically developed over the past five decades. There are two main groups:

- Chemically novel bioplastics: These have a different chemical structure than their fossil-based counterparts. A well-known example is polylactic acid (PLA).

- Drop-in plastics: They have the same chemical structure as conventional plastics but are made from bio-based materials such as bio-PE (bio-based polyethylene).

It is important to note that: Bioplastics can be both biodegradable and durable. Durable variants are ideal for long-lasting construction products, especially when they are recyclable, as many of these types are. Currently, bioplastics account for only about 1% of the global market. Their main application so far has been in packaging

Bioplastics at a glance

3D facade made of flax, bioplastics, and corrugated cardboard1 Bioplastics at a glance2 3D facade made of flax, bioplastics, and corrugated cardboard

Applications in construction

Interest in using bioplastics in construction is steadily growing, though their use is still limited. More and more companies are adding these products to their portfolios. Products already available on the market include:

- Insulation boards made from natural fibers with PLA reinforcement fibers

- Wall anchors made from bio-based polyamide (Bio-PA)

- Floor coverings based on PLA and recycled plastics

- Wood adhesives based on bio-PUR, PLA, and starch-based plastics

- Filler beads made from wood fibers and biodegradable bioplastics for transporting and storing panels

While producing pipes, cables, and window frames from bio-PE, bio-PP, or bio-PVC is technically possible, it is not economically feasible.

The Federal Ministry of Agriculture and Food (BMLEH) is promoting the development of such building products as part of its „Sustainable Renewable Resources“ program. One example: In Chemnitz, an LED-backlit 3D facade made of flax, bioplastics, and corrugated cardboard was installed on the richter & heß VERPACKUNGS-SERVICE GmbH building. Project partners included Chemnitz University of Technology and Fiber-Tech Construction GmbH.

Another area of research funding focuses on developing extruded insulation boards made from bioplastics. The Fraunhofer Institute for Wood Research (WKI) is working on this project, among others.

Bioplastics in construction

Advantages

- Reducing fossil resources

- Reducing CO2 emissions

- Wide range of applications

- Complementing traditional materials, such as wood

- Potential for new manufacturing processes, such as 3D printing

Challenges

- Costs: bioplastics are still more expensive than conventional alternatives

- Availability: low production capacities and incomplete supply chains

- Standardization and approval: a lack of standards and testing procedures complicates application

- Long-term behavior: a lack of long-term experience with construction applications

- Avoidance of ingredients that are harmful to health and/or the environment

More information

- Agency for Renewable Resources (FNR): Bioplastics

- Fraunhofer Institute: Bio-based plastics

- nova Institute: Renewable Carbon Initiative

Bioplastics do not compete with wood and other building materials made from renewable resources. Rather, they complement them, especially for complex geometries or 3D printing. 3D printing is increasingly being used for prototypes, interior design, and temporary structures.

Outlook

As awareness of sustainability grows and environmental regulations become stricter, demand for alternative materials in the construction industry is increasing. Bioplastics offer versatile solutions and help reduce the industry’s ecological footprint.

The following factors are crucial for their long-term success:

- Acceptance within the construction industry

- Development of uniform standards and norms

- Economic scaling of production

The construction industry is transitioning from fossil fuels to renewable resources. Bioplastics will be key to sustainable construction in the future.

Additional thoughts by the IBN

Bioplastics are a promising alternative to petroleum-based plastics. However, they may contain ingredients that are harmful to health and/or the environment. For example, additives designed to enhance durability, flexibility, color, or ease of processing can be harmful. Many of these additives, including stabilizers, plasticizers, colorants, and flame retardants, are not bio-based and can be released through abrasion, heating, or improper disposal.

Throughout the life cycle of bioplastics – development, production, use, recycling, and disposal – the IBN advocates the following criteria.

- First, ingredients that cause health and environmental problems should be avoided as much as possible (including microplastics in durable bioplastics).

- For many applications, natural materials made from renewable resources or minerals are available that do not require problematic additives and offer a better environmental performance. These materials should always be used instead.

This is a translation of “Biobasierte Kunststoffe im Bauwesen “

Translator

Katharina Gustavs is a Building Biology Professional in Victoria, Canada, who translated the Building Biology Online Course IBN.

info@katharinaconsulting.com | katharinaconsulting.com

Ihre Stimme zählt

Kommentarregeln:

Wir sind neugierig, was Sie zu sagen haben. Hier ist Raum für Ihre Meinung, Erfahrung, Stellungnahme oder ergänzende Informationen. Bitte beachten Sie bei Ihrem Kommentar folgende Regeln:

- Bitte keine Fragen: Auf dieser kostenlosen Informationsplattform können wir keine Fragen beantworten - bitte stellen Sie Ihre Fragen direkt an unsere Autor*innenAutor*innen.

- Bitte keine Werbung: Gerne können Sie auf Ihre Produkte/Dienstleistungen mit einem Werbebanner aufmerksam machen.

Wie werde ich

Baubiolog*in IBN?

How to become a Building Biology Consultant IBN?

Nachhaltig weiterbilden

Know-how, Zusatzqualifikationen und neue berufliche Möglichkeiten für Baufachleute sowie alle, die sich für gesundes, nachhaltiges Bauen und Wohnen interessieren.

Unser Kompetenz-Netzwerk

Hier finden Sie unsere qualifizierten Baubiologischen Beratungsstellen und Kontakte im In- und Ausland nach Standort und Themen sortiert.

Über die Baubiologie

Die Baubiologie beschäftigt sich mit der Beziehung zwischen Menschen und ihrer gebauten Umwelt. Wie wirken sich Gebäude, Baustoffe und Architektur auf Mensch und Natur aus? Dabei werden ganzheitlich gesundheitliche, nachhaltige und gestalterische Aspekte betrachtet.

25 Leitlinien

Für einen schnellen, aufschlussreichen Überblick haben wir in 25 Leitlinien der Baubiologie die wichtigsten Parameter herausgearbeitet, sortiert und zusammengefasst. In 15 Sprachen, als PDF oder als Plakat erhältlich.

0 Kommentare